How reliable is the high strength of the ceramic plunger under high pressure conditions?

Release Time : 2024-12-06

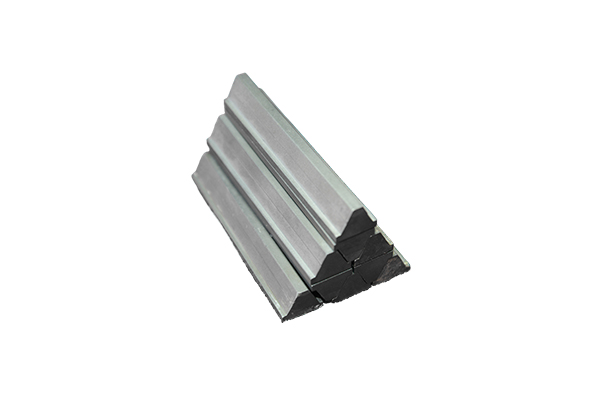

In many industrial application scenarios with high pressure conditions, such as high pressure pumps, metering pumps and other equipment, the ceramic plunger has shown extremely high reliability with its excellent high strength characteristics, making it an ideal choice for key components.

The high strength of the ceramic plunger is first reflected in its ability to withstand huge pressure without deformation or damage. Under high pressure conditions, the plunger needs to frequently withstand the strong force from the fluid, and general materials are prone to bending, breaking and other failures under such high pressure impact. Ceramic materials have extremely high compressive strength. For example, the compressive strength of alumina ceramic plungers can reach several GPa. This allows it to maintain its shape and structural integrity under the extrusion of high-pressure liquid or gas, stably reciprocate in the pump body, accurately complete the medium delivery or metering tasks, and ensure that the normal operation of the entire equipment will not be interrupted due to insufficient strength of the plunger.

Its high strength characteristics are also closely related to the dense microstructure of the ceramic plunger. The crystal structure inside the ceramic is tightly arranged, and the atomic bonding force is strong. This structure gives it excellent resistance to external force damage. In a high-pressure environment, even if subjected to repeated pressure loading and unloading cycles for a long time, the ceramic plunger is not prone to fatigue cracks or accumulation of internal damage. In contrast, some metal plungers are prone to fatigue failure under long-term high-pressure alternating stress, while the ceramic plunger can maintain reliable performance, greatly extending the maintenance cycle and service life of the equipment, and reducing the company's operating costs and downtime risks.

In addition, the high strength of the ceramic plunger helps to maintain good sealing performance. Under high-pressure conditions, the reliability of the seal is crucial, and any tiny leak may lead to reduced equipment efficiency or even failure. Since the ceramic plunger does not deform under high pressure, it can closely cooperate with the sealing components of the pump body to form a stable and reliable sealing interface, effectively preventing the leakage of high-pressure media. For example, in the high-precision metering pumps in the chemical industry, the ceramic plunger can accurately control the delivery volume of chemical reagents with its sealing effect guaranteed by its high strength, avoiding product quality fluctuations and environmental pollution caused by leakage.

Furthermore, the high-strength characteristics of the ceramic plunger enable it to adapt to harsh working environments. In addition to high pressure, there may also be factors such as high temperature and corrosive media. The high temperature resistance and chemical stability of ceramic materials combined with high strength further enhance their reliability under complex high-pressure conditions, providing a solid guarantee for the stable and efficient operation of industrial production processes.

In summary, the high-strength characteristics of ceramic plungers have excellent reliability under high-pressure conditions, from bearing pressure, anti-fatigue, ensuring sealing to adapting to harsh environments, etc., which demonstrates its indispensable and important value in the industrial field.

The high strength of the ceramic plunger is first reflected in its ability to withstand huge pressure without deformation or damage. Under high pressure conditions, the plunger needs to frequently withstand the strong force from the fluid, and general materials are prone to bending, breaking and other failures under such high pressure impact. Ceramic materials have extremely high compressive strength. For example, the compressive strength of alumina ceramic plungers can reach several GPa. This allows it to maintain its shape and structural integrity under the extrusion of high-pressure liquid or gas, stably reciprocate in the pump body, accurately complete the medium delivery or metering tasks, and ensure that the normal operation of the entire equipment will not be interrupted due to insufficient strength of the plunger.

Its high strength characteristics are also closely related to the dense microstructure of the ceramic plunger. The crystal structure inside the ceramic is tightly arranged, and the atomic bonding force is strong. This structure gives it excellent resistance to external force damage. In a high-pressure environment, even if subjected to repeated pressure loading and unloading cycles for a long time, the ceramic plunger is not prone to fatigue cracks or accumulation of internal damage. In contrast, some metal plungers are prone to fatigue failure under long-term high-pressure alternating stress, while the ceramic plunger can maintain reliable performance, greatly extending the maintenance cycle and service life of the equipment, and reducing the company's operating costs and downtime risks.

In addition, the high strength of the ceramic plunger helps to maintain good sealing performance. Under high-pressure conditions, the reliability of the seal is crucial, and any tiny leak may lead to reduced equipment efficiency or even failure. Since the ceramic plunger does not deform under high pressure, it can closely cooperate with the sealing components of the pump body to form a stable and reliable sealing interface, effectively preventing the leakage of high-pressure media. For example, in the high-precision metering pumps in the chemical industry, the ceramic plunger can accurately control the delivery volume of chemical reagents with its sealing effect guaranteed by its high strength, avoiding product quality fluctuations and environmental pollution caused by leakage.

Furthermore, the high-strength characteristics of the ceramic plunger enable it to adapt to harsh working environments. In addition to high pressure, there may also be factors such as high temperature and corrosive media. The high temperature resistance and chemical stability of ceramic materials combined with high strength further enhance their reliability under complex high-pressure conditions, providing a solid guarantee for the stable and efficient operation of industrial production processes.

In summary, the high-strength characteristics of ceramic plungers have excellent reliability under high-pressure conditions, from bearing pressure, anti-fatigue, ensuring sealing to adapting to harsh environments, etc., which demonstrates its indispensable and important value in the industrial field.