What is the hardness formation mechanism of tungsten carbide?

Release Time : 2025-02-26

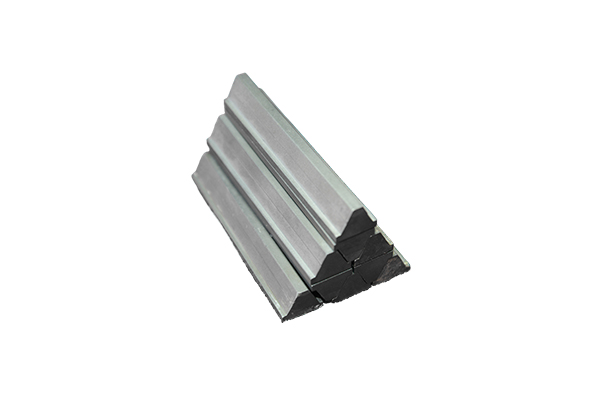

Tungsten carbide, with its excellent hardness and wear resistance, plays a vital role in many industrial fields. The reason why this material has such excellent hardness is mainly due to its unique chemical composition, crystal structure and preparation process.

The chemical formula of tungsten carbide is WC, which is a carbide ceramic material. In its chemical composition, tungsten carbide occupies a dominant position, and this compound itself has extremely high hardness. Tungsten is a metal element with a high melting point. When combined with carbon, the tungsten carbide formed has a hardness that even exceeds quartz and some diamonds. This high hardness foundation has laid a solid foundation for the application of tungsten carbide in various fields.

In addition to the chemical composition, the crystal structure of tungsten carbide is also a key factor in the formation of its hardness. Tungsten carbide has a cluster crystal structure with a small lattice constant, a close arrangement of unit cells, and a strong bonding force. This structure enables tungsten carbide to effectively resist deformation and damage when subjected to external forces. In addition, the crystal structure of tungsten carbide contains a variety of bonding methods such as metal bonds, ionic bonds and covalent bonds. These bonds have high bonding strength, forming a stable crystal structure, which further enhances its hardness.

The preparation process also has a significant effect on the hardness of tungsten carbide. Commonly used methods for preparing tungsten carbide include hot pressing, plasma sintering and high-temperature reaction sintering. Among them, high-temperature reaction sintering can produce tungsten carbide materials with fine grains and uniform structure. Fine grains mean more grain boundaries, which can more effectively prevent the expansion of cracks, thereby improving the toughness of the material. At the same time, uniform organization also helps to improve the overall performance of the material, including hardness.

The hardness of tungsten carbide is the result of the combined effect of its chemical composition, crystal structure and preparation process. This high hardness makes tungsten carbide have broad application prospects in the fields of cutting tools, molds, abrasives, etc. For example, in tool manufacturing, tungsten carbide tools can significantly improve cutting efficiency and tool life; in mold manufacturing, tungsten carbide molds can withstand higher pressure and temperature, improving mold life and product quality.

In summary, the hardness formation of tungsten carbide is a complex process involving multiple factors. It is this unique property that makes tungsten carbide an indispensable and important material in many industrial fields.

The chemical formula of tungsten carbide is WC, which is a carbide ceramic material. In its chemical composition, tungsten carbide occupies a dominant position, and this compound itself has extremely high hardness. Tungsten is a metal element with a high melting point. When combined with carbon, the tungsten carbide formed has a hardness that even exceeds quartz and some diamonds. This high hardness foundation has laid a solid foundation for the application of tungsten carbide in various fields.

In addition to the chemical composition, the crystal structure of tungsten carbide is also a key factor in the formation of its hardness. Tungsten carbide has a cluster crystal structure with a small lattice constant, a close arrangement of unit cells, and a strong bonding force. This structure enables tungsten carbide to effectively resist deformation and damage when subjected to external forces. In addition, the crystal structure of tungsten carbide contains a variety of bonding methods such as metal bonds, ionic bonds and covalent bonds. These bonds have high bonding strength, forming a stable crystal structure, which further enhances its hardness.

The preparation process also has a significant effect on the hardness of tungsten carbide. Commonly used methods for preparing tungsten carbide include hot pressing, plasma sintering and high-temperature reaction sintering. Among them, high-temperature reaction sintering can produce tungsten carbide materials with fine grains and uniform structure. Fine grains mean more grain boundaries, which can more effectively prevent the expansion of cracks, thereby improving the toughness of the material. At the same time, uniform organization also helps to improve the overall performance of the material, including hardness.

The hardness of tungsten carbide is the result of the combined effect of its chemical composition, crystal structure and preparation process. This high hardness makes tungsten carbide have broad application prospects in the fields of cutting tools, molds, abrasives, etc. For example, in tool manufacturing, tungsten carbide tools can significantly improve cutting efficiency and tool life; in mold manufacturing, tungsten carbide molds can withstand higher pressure and temperature, improving mold life and product quality.

In summary, the hardness formation of tungsten carbide is a complex process involving multiple factors. It is this unique property that makes tungsten carbide an indispensable and important material in many industrial fields.